Metal marking is a critical process in modern manufacturing industries across Bangladesh. From serial numbers and QR codes to brand logos and regulatory markings, permanent and high-contrast metal marking ensures product traceability, quality control, and brand credibility.

At Bengal CKD Laser, we work closely with factories, purchasing managers, and industrial decision makers to help them choose the right laser marking technology based on production needs, material type, and long-term ROI.

So, which laser technology is best for metal marking—and why do most industries rely on fiber lasers? Let’s explore.

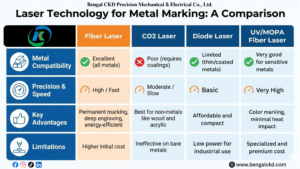

Which Laser Technology Is Best for Metal Marking?

For industrial applications, fiber laser marking machines are widely considered the most effective and reliable solution for metal marking.

Fiber lasers are capable of producing permanent, high-precision marks on a wide range of metals, including:

- Stainless steel

- Mild steel and carbon steel

- Aluminum and anodized aluminum

- Brass and copper

- Titanium and metal alloys

Compared to CO₂ and diode laser machines, fiber lasers offer superior marking speed, accuracy, and durability—making them ideal for industrial production environments in Bangladesh.

For most factories, fiber laser marking machines provide the best balance between performance and long-term value.

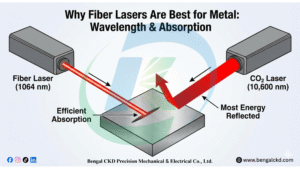

Why Fiber Lasers Perform Better on Metal

The main reason fiber lasers outperform other technologies lies in how metals absorb laser energy.

1. Optimized Wavelength for Metal Absorption

Fiber lasers operate at a 1064 nm wavelength, which is efficiently absorbed by metal surfaces. This allows the laser to interact directly with the material, producing clear and permanent marks without coatings or surface treatment.

In contrast:

- CO₂ lasers operate at a 10,600 nm wavelength

- Metals reflect most of this energy, resulting in weak or invisible marks

This is why CO₂ lasers are suitable for non-metal materials but not recommended for bare metal marking.

2. High-Speed and High-Precision Marking on Metal

Industrial fiber laser machines offer:

- Marking speeds up to 8,000 mm/s

- Micron-level precision for fine details

- Excellent depth control for engraving, annealing, and surface marking

For manufacturers, this means faster cycle times, consistent quality, and readable barcodes or data matrix codes even on small metal parts.

3. Minimal Heat-Affected Zone

Fiber lasers concentrate energy precisely where needed, resulting in:

- Minimal heat distortion

- Reduced risk of warping on thin metal sheets

- Clean marks without damaging surrounding areas

This is particularly important for automotive parts, electronics components, and precision engineering products.

4. Low Maintenance and Long Service Life

From a cost and operational perspective, fiber laser marking machines offer strong advantages:

- No consumables (no ink, chemicals, or coatings)

- Laser source life exceeding 50,000 hours

- Lower power consumption

- Minimal maintenance requirements

These benefits make fiber lasers a smart long-term investment for high-volume industrial production.

When to Choose MOPA or UV Fiber Laser Machines for Metal Marking

While standard fiber lasers meet most metal marking requirements, some applications benefit from advanced laser variants.

MOPA Fiber Laser Marking Machines

Best suited for:

- Color marking on anodized aluminum

- High-contrast black marking on stainless steel

- Applications requiring precise pulse control

UV Laser Marking Machines

Ideal for:

- Highly reflective metals like copper

- Thin or heat-sensitive components

- Micro-marking with minimal thermal impact

At Bengal CKD Laser, we help customers select the most suitable laser configuration based on application needs and production goals.

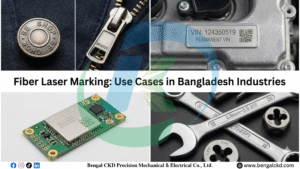

Bangladesh Industry Use Cases for Fiber Laser Marking on Metal

Fiber laser marking machines are widely adopted across key industries in Bangladesh due to their reliability, speed, and low operating cost.

Garments & Apparel Metal Accessories

Bangladesh’s garments industry uses fiber laser marking for:

- Stainless steel buttons, zippers, and metal labels

- Permanent brand logos and batch codes

- High-speed marking without damaging finished accessories

Automotive & Motorcycle Parts

Local manufacturers and assemblers use fiber laser marking to mark:

- Engine parts and metal housings

- VIN codes, serial numbers, and QR codes

- Heat-resistant, long-lasting marks for traceability

Electronics & Electrical Components

Fiber lasers are ideal for:

- PCB metal shields

- Electrical panels and nameplates

- Micro-marking on small precision parts without heat distortion

Light Engineering & Tool Manufacturing

Workshops and factories across Bangladesh rely on fiber lasers for:

- Tools, dies, and molds

- Industrial components requiring deep engraving

- Consistent marking for export-oriented products

Why Choose Bengal CKD Laser in Bangladesh?

Bengal CKD Laser is a trusted supplier of fiber laser marking machines, laser cutting machines, and laser welding solutions for industrial clients across Bangladesh.

We offer:

- Industry-proven laser machines imported from reliable manufacturers

- Technical consultation for machine selection

- After-sales support and service

- Solutions tailored to local production environments

Final Thoughts

For factory owners, purchasing managers, and industrial decision makers, fiber laser technology is the most reliable and cost-effective solution for metal marking.

With high speed, precision, durability, and low operating costs, fiber laser marking machines have become the industry standard.

If you are planning to upgrade or invest in a metal marking solution in Bangladesh, Bengal CKD Laser is ready to support you with the right technology and expertise.

2 Responses

Hey, I’m checking you out! Show me more of what you got. Solid machines and good services and I’m in. Let’s roll some business! bbenterprise

Hey, quick shoutout to Bengal CKD. Their machine performance is smooth and fast, and the customer support is good. Check and see which machine fits your need: GZone Business