The right fiber laser marking machine can significantly improve your production speed, marking precision, and business profitability. Whether you’re engraving metal components, branding industrial tools, or creating high-contrast black marks on plastics, understanding the key technical specifications will help you select the perfect model for your manufacturing or customization needs.

Fiber Laser Machine for:

• Stainless Steel

• Aluminum

• Brass

• Copper

• Titanum

• PlasticsS

• Coated Metals

• ABS, PVC, and more

This comprehensive guide breaks down the essential parameters of fiber laser marking machines—laser power, marking depth, area options, speed, and power supply—so you can confidently choose the right configuration for your industrial or commercial workflow.

Why Choose a Fiber Laser Marking Machine for Industrial Marking?

Fiber laser marking machines are the industry standard for high-precision metal and plastic marking. They offer extremely fine beam quality, long lifespan, and outstanding marking clarity on a wide variety of materials, including:

- Stainless Steel

- Aluminum (bare or anodized)

- Brass & Copper

- Hard Plastics

- Coated Surfaces

- ABS & PVC

- Metal Tools

- Industrial Components

If your business involves serial numbers, barcodes, QR codes, part identification, branding, or deep engraving, a fiber laser system is one of the most reliable and cost-efficient solutions available.

View Our Fiber Laser Marking Machines Collection

Key Specifications of our Fiber Laser Marking Machines

Choosing the right fiber laser marking machine requires understanding the six core specifications that impact performance.

Laser Power (20W / 30W / 50W / 100W)

Laser power determines engraving depth, clarity, and speed. Different power levels suit different application needs.

| Power | Ideal Application |

| 20W | Fine marking on plastics, electronics, coated metals, barcodes, and serial numbers. |

| 30W | Best for faster metal marking, deep engraving on light metals, and high-daily workloads. |

| 50W | Perfect for deep metal engraving, high-contrast marking, and thicker materials. |

| 100W | Heavy-duty industrial use—deep engraving, black engraving on stainless steel, and bulk production. |

Rule of thumb: Higher wattage = faster production + deeper, clearer marks. For medium-to-high volume metal processing, 30W–50W is the ideal range.

Marking Area (110×110 mm to 300×300 mm)

The marking area depends on the F-theta lens used. Larger areas offer more flexibility but slightly reduce precision.

| Lens/Area Options | Best Use Case |

| 110×110 mm | Highest precision for small parts, tools, serial numbers, and electronics. |

| 160×160 mm | Best balance of precision & workspace—ideal for most industrial applications. |

| 180×180 mm | Great for medium-sized components and metal plates. |

| 200×200 mm | More workspace for bigger items or batch marking. |

| 300×300 mm | Large signage, sheet material, and high-volume engraving. |

How to choose: Small items → 110–160 mm Large plates or multiple pieces → 200–300 mm

Marking Depth (0.01–2 mm Depending on Material)

Marking depth is influenced by:

- Laser wattage

- Material hardness

- Lens type

- Marking speed

For identification marks, 0.01–0.3 mm is sufficient.

For metal deep engraving, logos, or jewelry, 50W–100W is strongly recommended.

Marking Speed (<10,000 mm/s)

Fiber laser galvo systems offer extremely fast engraving speeds. High-speed marking provides:

- Higher daily output

- Faster production cycles

- Lower labor cost

- Increased profitability

Even at very high speeds, fiber lasers maintain excellent precision thanks to their galvanometer scanning head.

Lens Selection (Critical But Often Ignored)

Each marking area requires a matching F-theta lens, affecting:

- Beam spot size

- Detail resolution

- Engraving DPI

- Focus distance

- Overall marking quality

General rule:

Small lens → High precision

Large lens → Large area but slightly lower detail

For industrial metal parts or micro-marking, prioritize smaller lenses.

Power Supply (220V/50Hz)

Most fiber laser marking machines operate on 220V/50Hz, which is standard in Asia, Europe, and Africa.

If you’re operating in 110V regions:

- Use a transformer, or

- Request a factory-configured 110V variant

Stable power ensures consistent laser output and longer machine lifespan.

Matching Fiber Laser Specifications to Your Business Needs

Here’s a simplified selection guide to help you pick the right fiber laser configuration.

| Business Need | Recommended Power | Best Marking Area | Notes |

| Metal tools, cutlery, hardware | 30W–50W | 110×110 mm | Precise, durable marking for industrial components. |

| Deep metal engraving (jewelry, steel plates) | 50W–100W | 160×160 mm | Required for deep/black engraving. |

| Electronic parts, small components | 20W–30W | 110×110 mm | Ideal for small and detailed serial marking. |

| Plastic marking (ABS, PVC, keycaps) | 20W | 110×110 mm | Clean black marking on plastics. |

| Large metal plates or signage | 50W–100W | 200×300 mm | Larger area + higher power needed. |

| Mixed-material commercial engraving | 30W–50W | 160×200 mm | Versatile for daily engraving orders. |

Choose based on your material type, production scale, and marking size.

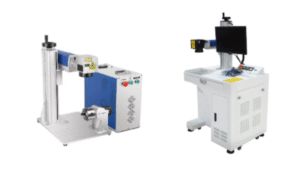

Portable vs. Desktop Fiber Laser Marking Machine Options – View here

Fiber laser markers generally come in two major formats:

Portable / Open-Type Fiber Laser Marker

- Lightweight and easy to move

- Perfect for workshops, shops, and on-site engraving

- Ideal for small tools, accessories, and metal tags

Desktop / Enclosed Fiber Laser Marker

- Fully enclosed safety cabinet

- Better for factory environments

- Stable for continuous, high-volume production

- Enhanced safety for operators

Your choice depends entirely on workspace requirement and production style.

Final Recommendation for Selecting a Fiber Laser Marking Machine

Choosing the right fiber laser marking machine requires balancing power, marking area, precision, and production volume. With power options from 20W to 100W and marking areas ranging from 110 mm to 300 mm, you can easily configure a setup tailored to your exact business needs.

A well-selected fiber laser machine will significantly boost output, improve marking quality, and increase profitability for your business.