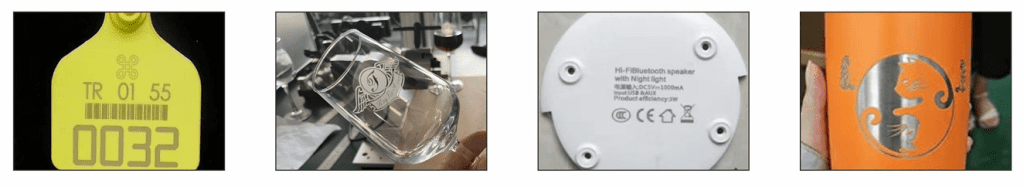

The right UV laser marking machine can significantly improve your production speed, marking precision, and overall efficiency—especially when working with delicate, heat-sensitive materials. Whether you’re engraving plastics, marking electronic components, coding packaging, or creating ultra-fine graphics, understanding the key technical specifications will help you select the perfect UV laser marking machine model for your manufacturing or customization workflow.

UV Laser MarkingMachine for:

-

ABS

• PVC

• Glass

• Acrylic

• Ceramics

• Silicone

• Plastic Packaging

• Electronic Components

• Coated Surfaces

• Leather

• and more

This comprehensive guide breaks down the essential parameters of UV laser marking machines—laser power, marking depth, area options, speed, lens selection, and power supply—so you can confidently choose the right configuration for your production environment.

Why Choose a UV Marking Machine for Precision Marking?

UV marking machines are the industry standard for high-precision, low-heat marking, especially on materials where fiber or CO₂ lasers may cause burning, melting, or deformation. Using a 355nm wavelength, UV lasers offer:

-

Extremely fine beam quality

-

High-resolution marking

-

Minimal thermal effect

-

Compatibility with a wide range of sensitive materials

Ideal materials include:

-

ABS, PVC, PET

-

Acrylic & Glass

-

Leather

-

Ceramics

-

Silicone & Rubber

-

Coated Surfaces

-

Medical Plastics

-

Electronic Components

-

Food & Cosmetic Packaging

View Our UV Laser Marking Machines Collection

Key Specifications of Our UV LaserMarking Machines

Choosing the right UV laser marking machine requires understanding the six core specifications that impact performance.

Laser Power (3W / 5W / 10W / 15W)

Laser power determines marking speed, clarity, and compatibility with different materials.

|

Power |

Ideal Application |

|

3W |

Ultra-fine marking on plastics, microchips, PCBs, packaging. |

|

5W |

Faster marking on polymers, coated surfaces, thin metals. |

|

10W |

Industrial coding, glass marking, and high-speed batch production. |

|

15W |

High-volume manufacturing, deep marking on harder materials. |

Rule of thumb: Higher wattage = faster marking + improved contrast.

For daily production involving plastics or electronics, 3W–5W is ideal.

Marking Area (110×110 mm to 300×300 mm)

The marking area depends on the F-Theta lens. Larger lenses provide more workspace but slightly reduce precision.

|

Lens/Area Options |

Best Use Case |

|

110×110 mm |

Highest precision for micro-marking and small components. |

|

160×160 mm |

Best balance of detail and workspace. |

|

180×180 mm |

Good for medium-sized packaging and plastic products. |

|

200×200 mm |

Larger components or multi-item marking. |

|

300×300 mm |

Signage, large packaging sheets, and oversized items. |

How to choose:

Small/precision items → 110–160 mm

Bulk or large items → 200–300 mm

Marking Depth (0.01–0.2 mm Depending on Material)

Marking depth is influenced by:

-

Laser wattage

-

Material type

-

Lens selection

-

Marking speed

For packaging codes, medical plastics, and fine text, 0.01–0.05 mm is sufficient.

For deeper marks on glass or ceramics, 10W–15W is recommended.

Marking Speed (<10,000 mm/s)

UV galvo systems offer extremely fast marking speeds, enabling:

-

High production output

-

Faster batch processing

-

Reliable industrial marking

Even at high speeds, UV lasers maintain exceptional detail and clarity due to their ultra-fine beam diameter.

Lens Selection (Critical for UV Precision)

Lens selection affects:

-

Beam spot size

-

Detail resolution

-

Engraving DPI

-

Focus distance

-

Overall clarity

General rule:

Small lens → Highest precision

Large lens → Wider area with slight precision trade-off

For electronics and packaging codes, choose smaller lenses for best micro-marking quality.

Power Supply (220V/50Hz)

UV laser marking machines operate on standard 220V/50Hz industrial power.

For regions using 110V:

-

Use a voltage transformer

-

Or request factory-configured 110V support

Stable power ensures consistent laser output and long machine life.

Matching UV Laser Marking Machine Specifications to Your Business Needs

Below is a simplified guide to selecting the right configuration.

|

Business Need |

Recommended Power |

Best Marking Area |

Notes |

|

Plastic packaging, bottles, date codes |

3W–5W |

110×110 mm |

Ultra-fine marking, no burning. |

|

Electronics, PCBs, micro-components |

3W–5W |

110×110 mm |

Best for micro-marking and small text. |

|

Glass, acrylic, transparent materials |

5W–10W |

160×160 mm |

Clean and crack-free marking. |

|

Ceramics, coated materials |

10W–15W |

160×180 mm |

Higher power improves contrast. |

|

Large packaging sheets or signage |

10W–15W |

200–300 mm |

Larger area + faster production. |

|

Mixed-material commercial engraving |

5W–10W |

160–200 mm |

Versatile for daily orders. |

Choose based on material type, engraving size, and production volume.

Portable vs. Desktop UV Laser Marking Machine Options – View Here

UV marking machines typically come in two major formats:

Portable / Open-Type UV Marking Machine

-

Lightweight & easy to move

-

Ideal for shops, workshops, and mobile operations

-

Suitable for small tools, accessories, and packaging

Desktop / Enclosed UV Marking Machine

-

Closed safety cabinet

-

Best for factory environments

-

Stable for long, continuous output

-

Enhanced operator safety

Your choice depends on workspace layout and production style

Final Recommendation for Selecting a UV Marking Machine

Choosing the right UV laser marking machine requires balancing power, marking area, precision, and material compatibility. With power options from 3W to 15W, and marking areas from 110 mm to 300 mm, you can easily configure a UV laser system tailored to your exact business requirements.

A properly selected UV marking machine will significantly enhance marking clarity, reduce material damage, and increase your production efficiency and profitability